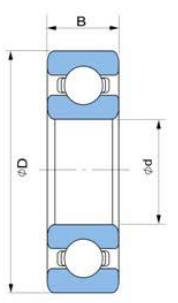

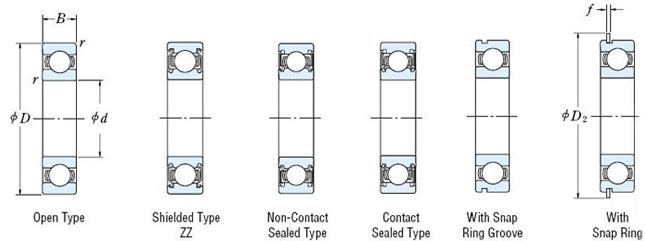

Deep Groove Ball Bearings is the most commonly used type in all kinds of bearings by the diversity of categories. They include certain types such as open type, two shields steel type or two contact seals and snap ring groove (N).

Deep Groove Ball Bearings has two shield steel type (ZZ), two contact seals (2RS) that is a standard bearing. Grooved surface and rolling on the rim of the outer ring bearings may offer a slightly larger radius than steel balls. The steel balls have contacts with grooves running (elliptical contact when there are loads). The edge of the rim of equal height (as the outer edge of the rim).

Deep Groove Ball Bearings can suffer radial loads, axial loads, loads compound and simple by design, types of bearings are manufactured to produce precision operation high and high-speed operation.

Deep Groove Ball Bearings have outer diameter less than 9mm called miniature bearings. Bearings with an outer diameter ≥ 9 mm and inner diameter <10 mm called small Deep Groove Ball Bearings.

The cage of bearings made of steel stamping. The cages are outsourced for use for bearings for high-speed operation or bearings with larger diameter. This design protects the lubricant avoid from contamination and ensure retention of lubricants with cage shape as blocking frame format

.png)